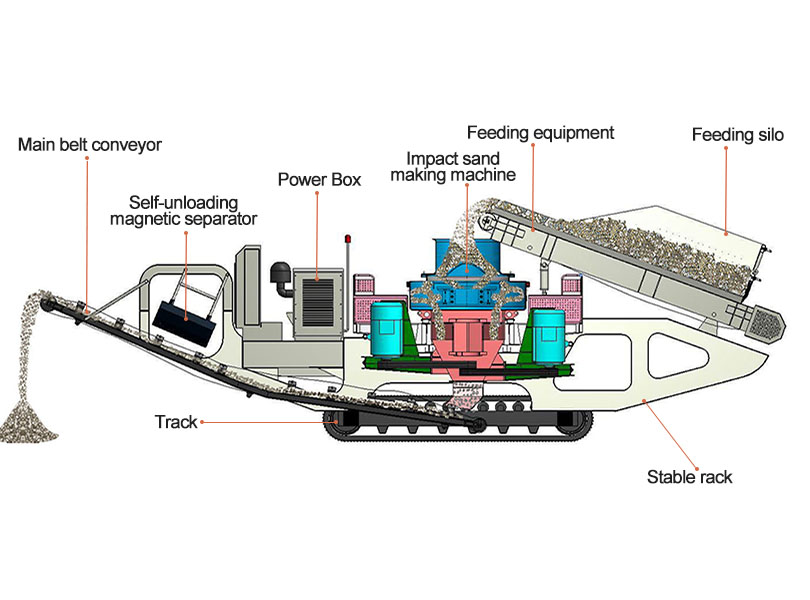

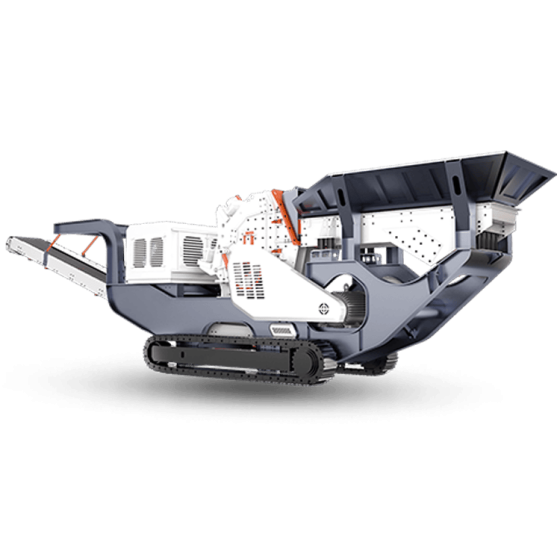

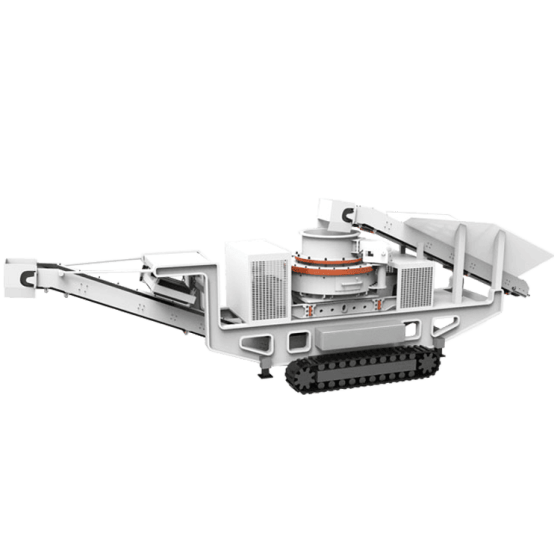

Tracked Mobile Sand Making Plant is a mobile sand making equipment that integrates crushing, screening and conveying functions. It is driven by a crawler chassis and can be flexibly transferred to other locations without external power.

It is widely used in mining, construction waste disposal, Construcción de carreteras y otros campos, and is especially suitable for construction scenes with complex terrain or requiring frequent movement.

Características técnicas

1. Alta movilidad

• The tracked chassis adapts to rough terrain and eliminates the need for a transport vehicle, saving time and costs.

• Supports “on-site crushing” to reduce energy consumption in material handling.

2. Control inteligente

• Equipped with a PLC touch screen system to monitor equipment status (such as current, temperature, and output) en tiempo real.

• Remote diagnostics function quickly troubleshoots faults and reduces the risk of downtime.

3. Environmentally friendly and energy-saving design

• The closed structure is equipped with dust removal and noise reduction devices (such as sprinkler system and sound insulation layer) to meet environmental protection standards.

• Optimize power matching and reduce fuel consumption by 15%-30% compared with traditional equipment.

4. Modular Integration

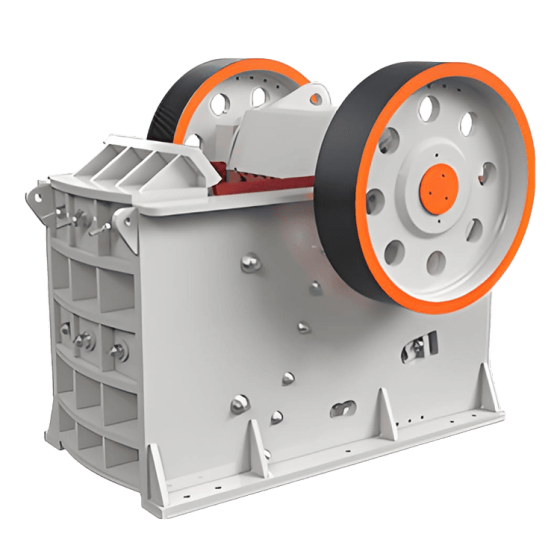

• The crusher, screener, conveyor belt and other modules are compactly arranged for easy maintenance.

• Supports quick replacement of accessories (such as screens, hammers) to meet different production needs.

5. Multifunctional adaptability

• It can process a variety of raw materials such as granite, basalt, construction waste, etc., and the output particle size is adjustable (0-5mm fine sand to 10-30mm crushed stone).

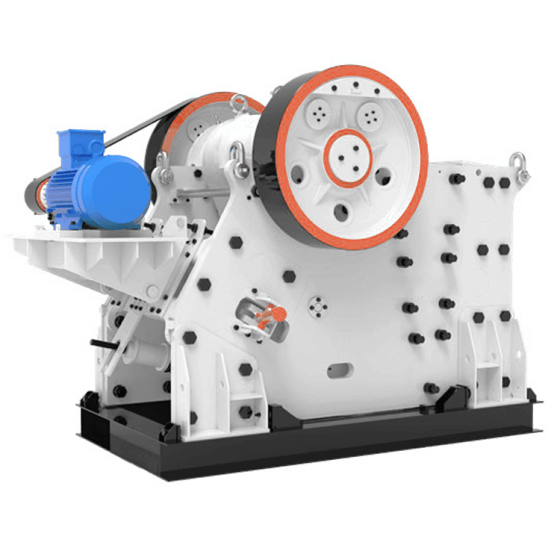

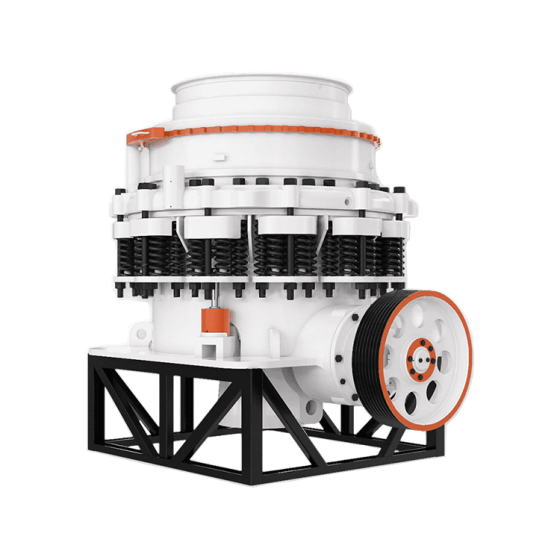

• Different crushing machines (such as cone crusher and jaw crusher) can be selected to meet diverse production scenarios.

Application Advantages

• Reduce operating costs: Save the capital construction costs of fixed production lines, suitable for short-term or decentralized projects.

• Improved quality of finished products: The impact crushing process ensures that the sand particles are cubic and well graded, suitable for high-standard concrete.

• Quick response to demand: The daily processing capacity of a single device can reach 50-500 Toneladas, and the production scale can be flexibly adjusted.

crusherfactory.com

crusherfactory.com